- +966-504827632

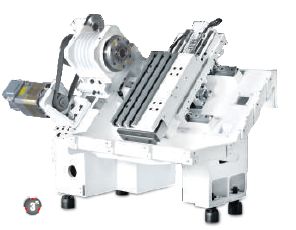

CNC Low Precision Turning Centers

Leading Manufacturers, Exporters, Wholesaler of DX 60 CNC Low Precision Turning Center, DX 100 CNC Low Precision Turning Center, DX 150 CNC Low Precision Turning Center, DX 200 CNC Low Precision Turning Center, DX 250 CNC Low Precision Turning Center, DX 350 CNC Low Precision Turning Center, DX 500 CNC Low Precision Turning Center, DXG 100 CNC Low Precision Turning Center, TS 120 CNC Low Precision Turning Center and VTL 500-750 CNC Low Precision Turning Center from .

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

We are dependable name, affianced in offering DX 60 CNC Low Precision Turning Center across the boundaries. We have adopted secure payment methods that are approved by authority and featured with options that facilitate quick transfers.

For small precision disc-type components in mass.

- Slant Bed Monoblock structure for rigidity even at higher dynamics. Better vibration damping for better tool life.

- Gang type Linear tooling for quick approach to job for unmatched tool change time.

- Completely compatible for productivity options like Part Catcher, Automatic Tool Setting. Integration with Bar Feeder, Gantry Auto Loading, Robot Arm etc...

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

Reckoned for the exceptional DX 100 CNC Low Precision Turning Center; we are a trustworthy Supplier in this domain. We have a team of quality inspectors who check the entire lot of raw material on several counts, prior to procurement. Thus, quality of the finished products is never fortified.

For small precision disc-type components in mass.

- Slant Bed Monoblock structure for rigidity even at higher dynamics. Better vibration damping for better tool life.

- Gang type Linear tooling for quick approach to job for unmatched tool change time.

- Completely compatible for productivity options like Part Catcher, Automatic Tool Setting. Integration with Bar Feeder, Gantry Auto Loading, Robot Arm etc...

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

Our policies regarding payment are simple and quick. We have ethical business standards, and we make sure our patrons can make payment securely along with documentation. Well-known Suppliers of DX 150 CNC Low Precision Turning Center; we are reckoned for the exceptional range of products that we offer.

Compact and Versatile

- Designed to produce small components and between center workpieces.

- Unique vertical (90 ) monoblock design providing stability with least distortion, even for smooth dry machining with heavy cuts for faster production.

- Vertical fall of chip and coolant, prevents damage to Linear Motion Guideways and Ball Screws, thus increasing overall machine life.

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

One of the most successful model in Indian Market. Your partner to deliver the optimum productivity with many features, delivering optimum performance to match demands of various workpiece size applications.

Step-up Structure concept with widely space guideways at higher tool life and least vibration even with hard material higher diameters. No vibration, means better surface finish even with grooving or threading materials.

Features :

- High duty spindle.

- Bi-directional servo turret.

- Precision & class LM Guide & direct couple ball screw.

- Tailstock with 1-V Type & 1-Flat Type Guide.

- Rear / Front chip conveyor option

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

These machines are for producing world class products, with quick, accurate output and with minimum non-productive time. Robust machining of bigger components that require higher cutting load with better dampening capacity maintaining consistent accuracy, marginally boosting working capability.

Features :

- 45° Slant Bed Monoblock Structure with improved bed twisting rigidity for heavy duty & dynamic load cutting

- Step-up structure for DX 250-500

- Wide precision class Linear Motion (Roller Type) Guideways with directly coupled Ball screws, for enhanced machining capability

- Capable to deliver best performance even in hard part machining

- Heavy duty spindle with angular contact bearing

- Bi- Directional Servo Tool Turret

- Special plunger system for feed control movement of tailstock

- Wider working area & Efficient Chip

- Disposal system

- Easy-to-operate operator panel for operator friendliness

- Gearbox option for application demanding higher torque at lower rpm

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

These machines are for producing world class products, with quick, accurate output and with minimum non-productive time. Robust machining of bigger components that require higher cutting load with better dampening capacity maintaining consistent accuracy, marginally boosting working capability.

Features :

- 45° Slant Bed Monoblock Structure with improved bed twisting rigidity for heavy duty & dynamic load cutting

- Step-up structure for DX 250-500

- Wide precision class Linear Motion (Roller Type) Guideways with directly coupled Ball screws, for enhanced machining capability

- Capable to deliver best performance even in hard part machining

- Heavy duty spindle with angular contact bearing

- Bi- Directional Servo Tool Turret

- Special plunger system for feed control movement of tailstock

- Wider working area & Efficient Chip

- Disposal system

- Easy-to-operate operator panel for operator friendliness

- Gearbox option for application demanding higher torque at lower rpm

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

An ideal partner for machining large diameter components used in heavy engineering industry such as automobile, oil & natural gas, earth moving, various allied and subcontracting industries.

Features :

- Bed & Saddle made from higher grade cast-iron for maximum rigidity, most suitable for hard part turning

- Offer wide range of cutting sizes along with rapid positioning & bidirectional turret, for unmatched cycle time.

- FEM proven construction to optimally work with high speed & heavy duty process forces with minimal vibrations

- Wide precision class Linear Motion (Roller Type) Guideways with directly coupled Ball screws, for enhanced machining capability

- Heavy duty spindle with angular contact bearing with option of gearbox for high torque at lower rpm

- Wider working area & Efficient Chip Disposal system

- Operator and TPM friendly

Turn-mill Option with Driven Tool Turret : Servo driven 12 Station -Live Tool Turret can be chosen for Turn-Mill Center version which allows mix and match of static or powered tools. Turret movement is controlled by High- Torque motor for various applications like PCD Drilling & Tapping, OD & ID profiles with Radial and Axial Live Tools.

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

An ideal solution for manufacturers looking for complete automation with mass productivity of chucker type components.

Features :

- Monoblock designed structure for better rigidity during full load conditions

- Special preloaded job conveyors for long unattended production

- Efficient chip removal system with free chip falls to match production rate

- Machine for flexible Machine utilization of 2 identical operations or 1 & 2 operations with Turn-around station option

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

Automation with twin turret, twin headstock & gantry arm for unintrupted mass production.

3-AXIS GANTRY ROBOT : High dynamic gantry with dual gripper swivel head helps instant and accurate automation Loading/ Unloading enabling long hours of unattended operation.

- Stroke (X/Y/Z) : 1850/560/150 mm

- Job Capacity : Ø 120 x 80 mm

| Business Type | Manufacturer, Exporter, Supplier |

Preferred Buyer From

| Location | All Countries |

VTL Series machines are specially designed for heavy and larger diameter component machining of heavy engineering industries like railways, heavy automobiles, oil &natural gas, compressor, power, earthmoving and other with addition to components like valves, pumps, motor bodies, gear blanks and components from various subcontracting industries.

Features :

- Box type design for heavy duty & dynamic load cutting

- High glade C.I. thermally stable bed & column

- Broad hardened and ground guide for rigidity at greater extension of turret

- Rigid structure with wider working area &

- Efficient Chip Disposal system

- Bi- Directional Servo Tool Turret

- Easy-to-operate operator panel for operator friendliness

- Hydraulic Counter Balancing system

- Ergonomic design for easy component loading / unloading

- Live Tool Turret option available for turning & milling in single set-up

3-SIDED ADJUSTABLE SUPPORTS FOR AXIS : 3-sided support on both X & Z - Axis helps maintaining tolerance between axis & guide-ways during reversal movement delivering long term accuracy and durability.